Isuzu Power Solutions Enhances Performance of Piranha Chippers

The performance of Australian-designed and manufactured Piranha Chippers' high-quality woodchipper units has recently caught the attention of arborists, local councils, and emergency services across the country.

With local and state councils increasingly focused on sustainability and environmentally conscious outcomes, Melbourne-based Piranha Chippers meets the demand for locally manufactured machinery that delivers outstanding performance.

“The rising frequency of severe weather events has driven massive demand for clean-up operations, and the interest in our chippers has been overwhelming,” said Nathan Sangster, Director of Piranha Chippers.

“With so many trees coming down, they need to be processed quickly, and our chippers can literally chew through fallen trees in seconds,” he added.

Piranha Chippers: Perfect for Clean-Up Operations

Piranha Chippers are designed for high-efficiency clean-up operations, quickly and effectively processing fallen trees. The byproduct of this work, chipped wood, is being used in a variety of industries.

“Chipped wood is becoming popular in stock farming for bedding, as well as in orchards, which often require large-scale tree disposal when trees reach the end of their productive life,” Nathan explained.

“Burning old trees is no longer an acceptable practice, so growers want a chipper that can handle large volumes reliably. As a bonus, they end up with mulch they can reuse to help regenerate new trees, which is a fantastic outcome.”

A New Player with a Focus on Sustainability

Although relatively new to the market, Piranha Chippers is positioning itself as a leader in delivering sustainable solutions to the growing demand for efficient tree-clearing equipment.

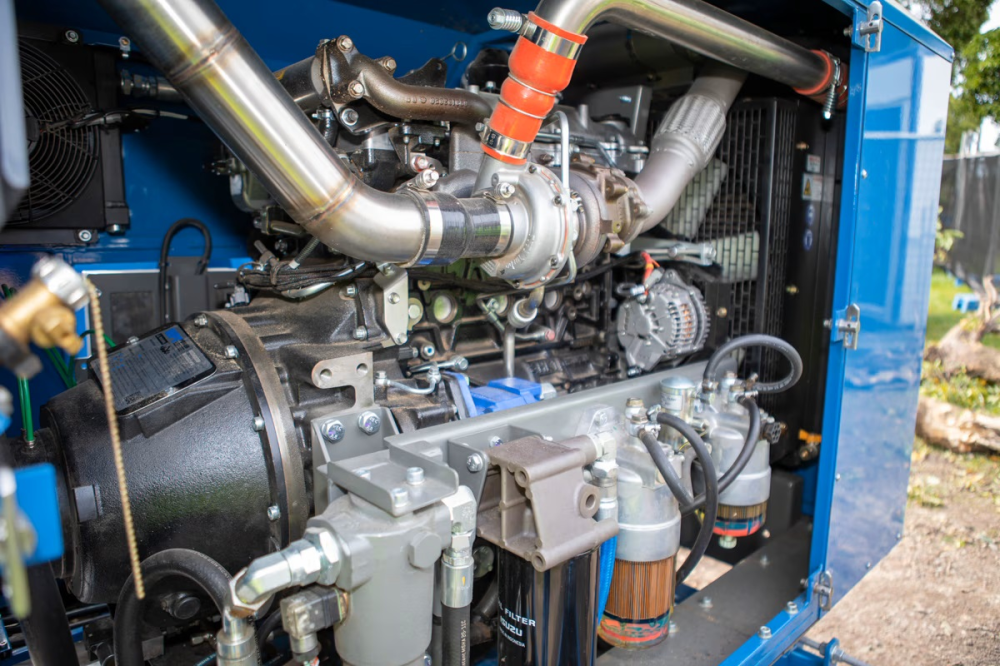

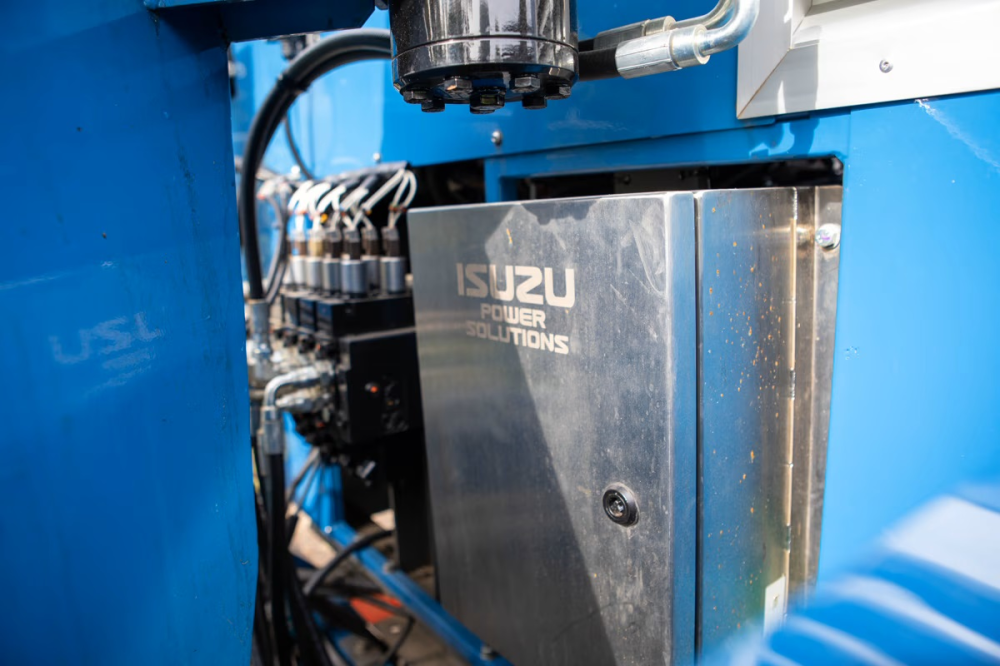

Initially exploring various design options, Nathan turned to local expertise to help refine the performance and power needs of their machines. After consulting with Isuzu Power Solutions, Piranha Chippers selected the 4HK1 power unit—a vertical, water-cooled, four-cylinder common rail engine.

With a power output of 147 kW (197 hp) @ 2,100 rpm, the 4HK1 engine drives the chipper’s drum system and powers the hydraulic pumps and electrical systems.

Nathan, who has experience with Isuzu trucks powered by the same engine, saw the opportunity to apply this reliable technology to their chippers.

“I’ve run Isuzu trucks in our other business and was keen to see if the same engine technology that powers those vehicles could work in our chippers,” Nathan said.

“Once we confirmed it, we worked closely with Isuzu engineers to ensure the power unit was designed to suit our specific needs, especially when it came to serviceability.”

Smart Design for Easy Serviceability

Isuzu’s design expertise ensured the chippers’ ancillaries, such as filters, were positioned at the front of the unit for easy access during maintenance. Nathan appreciates this simple yet critical feature, as it allows all service points to be accessed from a single location when the operator opens the bay door of a Piranha Chipper.

“The two key pillars we’ve built this machine on are performance and serviceability,” Nathan explained. “We have an engine that offers more power than the competition, and a design that allows easy access to all service points, backed by readily available consumables and replacement parts.”

“It’s the only chipper on the Australian market that offers simple access from one side, which has received very positive feedback from customers.”

Tested to the Limits in Harsh Conditions

The Australian environment provides the ideal testing ground for Piranha Chippers, with native tree species and rugged conditions putting the machines through their paces.

Nathan noted that the 4HK1 engine comes equipped with a telemetry system, allowing real-time performance data to be monitored remotely.

“We’ve been testing the chippers using Australian hardwoods, particularly gum trees, to really push the limits and ensure the machine meets the high standards customers expect,” he said.

“This kind of testing puts significant strain on every component of the chipper, but we’ve found that the engine’s exceptional power, coupled with a smart electronics system, ensures the machine only increases output when necessary.”

Looking to the Future

As Piranha Chippers grows over the next 12 months, the company plans to expand its manufacturing capabilities and hire a team of skilled workers to support production.

“We have the facilities to scale up, and we’re planning to bring in a wide range of new skills to help meet growing demand,” Nathan said.

“We’re seeing serious interest from customers who want to see the machine in action, and the support from partners like Isuzu Power Solutions gives us the confidence to keep moving forward.”

Found your perfect purchase? Let’s make financing just as easy!

Work with Australia’s best-reviewed finance broker for a great deal and a stress-free experience. With 2,500+ glowing Google reviews, you can trust you're in good hands! See what our happy customers say in Credit One reviews, or jump right in and crunch the numbers with our handy loan repayment calculator. Your ideal financing solution is just a few clicks away!