Our Bag-it 30 automated bagging machine comprises of an upgrade to the electronics package. The addition of a touch screen panel, controlled by a PLC ensures simplicity for the operator. This addition on top of the existing robust design has greatly increased the functionality of the machine.

The new upgrade enables the user to finetune their bagging requirements to suit their individual application. The only limitation is your imagination when it comes customising your Bag-it 30.

A range of optional extras are available to help tailor your machine to suit your application. Some of these features include weigh scales, remote air cannon activation, anti-slip detectors, anti-bridging detectors, and load out conveyor integration.

The Bag-It 30 covers a vast majority of applications from sand through to quarry rock and all things in between, and has the ability to achieve bagging rates of up to 240 bags per hour.

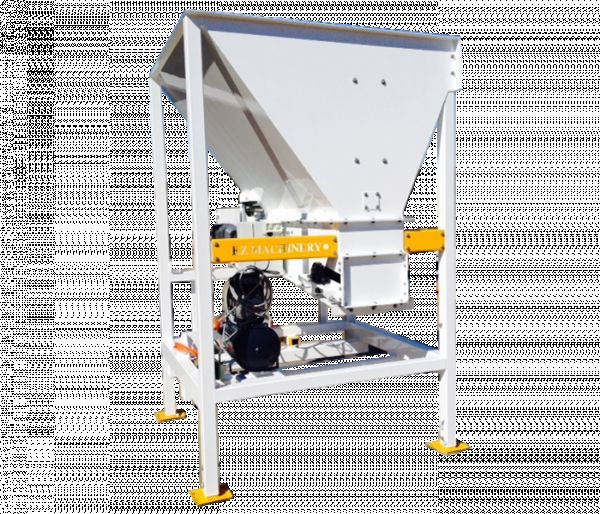

About The Bag-it 30 Bagging Machine

The sturdy Bag-it 30 consists of a 5mm plate hopper with an RHS supporting frame which is 100% Powder-coated after fabrication and comes standard with inbuilt forklift pockets for manoeuvrability. Complete with its own inbuilt air compressor, all you need to do is add 240v power and the machine is operational (Generator operation is also available).

The ergonomically designed height adjustable front load out roller conveyor enables the operator to adjust the working height of the machine to suit their individual requirements.

The bagging operation is controlled via two foot pedals based in front of the load out conveyor. The operator presses the first pedal to activate the pneumatic bag clamps and simultaneously starts the feed conveyor. Once the bag has reached the desired weight or level, the operator releases the pedal, which in turn releases the pneumatic bag clamps and enables the bag to moved on for sealing / stitching.

Given the variety in bagging applications, included in the purchase price, is a choice of either a sealer or stitcher. The heat sealer is operated by pressing the second pedal in front of the load out conveyor. The sealer has a pneumatic ram controlling this function, where the stitcher has a mount bracket and recoil unit.

A hinged inspection panel mounted on the top of the head box, makes it easy to check on the load out belt and feed chute. Each corner of the Bag-it 30 is fitted with adjustable legs to ensure that the machine is able to be levelled on uneven ground.

Located inside the hopper is a anti-bridging device fitted above the belt and is designed to free up moist or lumpy material, making a smooth and consistent flow rate.

The touch screen is mounted to the right hand side of the head box and is positioned at eye height to assist the operator in setting the operation parameters.

The 3m3 hopper is fitted standard with a removable hungry board on one side to assist in smaller loaders in filling the unit

-40243.png)